For cross-border e-commerce resellers and sourcing agents, maintaining consistent quality control (QC) across dozens of orders and suppliers can be a major operational headache. This is where the Pandabuy Spreadsheet emerges as an indispensable business tool. Far more than a simple list, it provides a structured, centralized system for standardizing the entire pre-shipment inspection process. It allows resellers to implement uniform QC standards that reduce errors, manage supplier performance, and build lasting client trust.

Creating Centralized QC Template Libraries

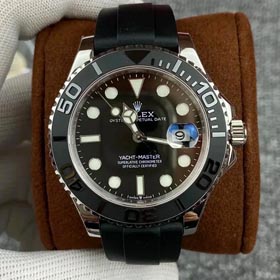

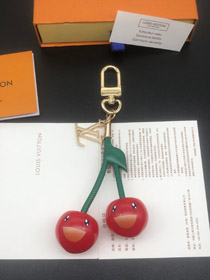

The core power of the Pandabuy Spreadsheet lies in its ability to house detailed, category-specific QC templates. Instead of relying on memory or scattered notes, resellers can define precise checkpoints for every product type. For instance, a clothing template would mandate checks for size accuracy (comparing labeled vs. actual measurements), fabric composition and weight, and the quality of stitching and seams. For cosmetics, the template focuses on packaging integrity, batch codes, expiry dates, and whether seals are intact. Electronics templates emphasize function testing, accessory completeness, and the absence of physical defects. Jewelry deserves particular attention, with templates specifying checks for metal purity stamps, stone settings (ensuring gems are secure), clasp functionality, and the presence of any plating flaws or discoloration.

Implementing a Clear QC Scoring & Resolution System

A standard pass/fail judgment is often too simplistic. The spreadsheet enables a nuanced scoring system, typically categorizing items as Excellent (exceeds expectations), Acceptable (meets all standards), or Unacceptable/Failed (has critical flaws). For every 'Unacceptable' rating, the spreadsheet requires logging the specific defect and the predetermined resolution action. This creates a clear audit trail. Was the item arranged for a return to the supplier? Was a replacement requested? Or was the item approved for a price reduction to compensate the end customer? Documenting this directly in the sheet eliminates guesswork and ensures consistent problem-solving.

Analyzing Supplier Performance & Strategic Sourcing

The true strategic advantage of this system is data aggregation. By logging QC results against specific suppliers over time, the spreadsheet automatically generates performance metrics. A reseller can quickly calculate the QC pass rate for each vendor, identifying which ones consistently deliver Excellent or Acceptable items. This transforms the Pandabuy Spreadsheet from a simple checklist into a powerful supplier management dashboard. Long-term, resellers can use this data to adjust their sourcing strategy—allocating more orders to high-performing suppliers and either retraining or phasing out unreliable ones. This proactive management is key to scaling a stable business.

Benefits: From Fewer Disputes to Greater Trust

A standardized QC workflow powered by the Pandabuy Spreadsheet delivers tangible business outcomes. By catching defects before shipment, it dramatically reduces costly post-sale returns and disputes. Sharing a summarized QC report (or the existence of this rigorous process) with clients becomes a powerful trust-building signal. It demonstrates professionalism and a genuine commitment to product quality, justifying premium service fees and encouraging repeat business. Ultimately, it shifts the reseller's role from a simple order-placer to a trusted quality assurance manager for their clientele.

For serious resellers in the cross-border e-commerce space, standardizing operations is non-negotiable. Tools like the Pandabuy Spreadsheet provide the framework to turn quality control from an unpredictable variable into a reliable, data-driven process. By implementing category templates, clear scoring, and supplier analytics, agents safeguard their reputation, optimize their supply chain, and deliver the consistent value that modern customers demand. This is especially critical when dealing with high-value categories like electronics, Jewelry, and designer goods, where the cost of a quality failure is highest.